Tank Cathodic Protection

Engineering & Design

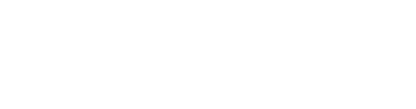

With the expertise of an AMPP CP4 specialist, we develop comprehensive cathodic protection systems for both the internal and external surfaces of tanks.

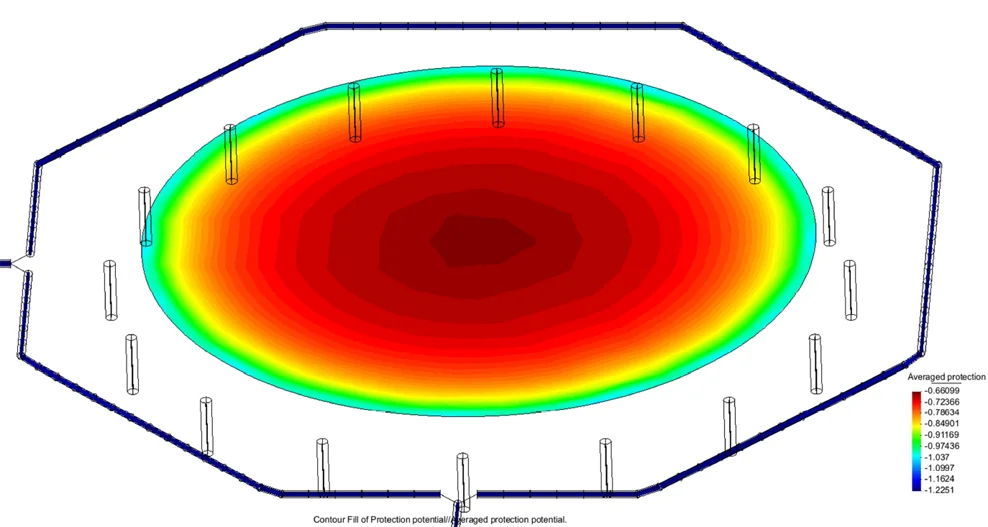

The process begins with gathering essential design data, either provided by the client or, if unavailable, inferred based on our knowledge and experience. Once the necessary parameters are established, we determine the appropriate sizing and distribution of system components. To ensure accuracy and effectiveness, the final design is modeled and validated through advanced simulations using Beasy CP® software.

For both galvanic and impressed current systems, we carefully determine the optimal type, quantity, and placement of anodes to ensure effective corrosion protection. Our designs also incorporate critical monitoring components, such as permanent reference electrodes and control anodes, to maintain system efficiency and reliability.

For impressed current systems, we also design the necessary infrastructure around the tank to establish proper connections between the anodes and the rectifier, ensuring seamless operation.

Finally, we provide a comprehensive bill of materials, complete with technical specifications, facilitating easy installation and long-term system performance.

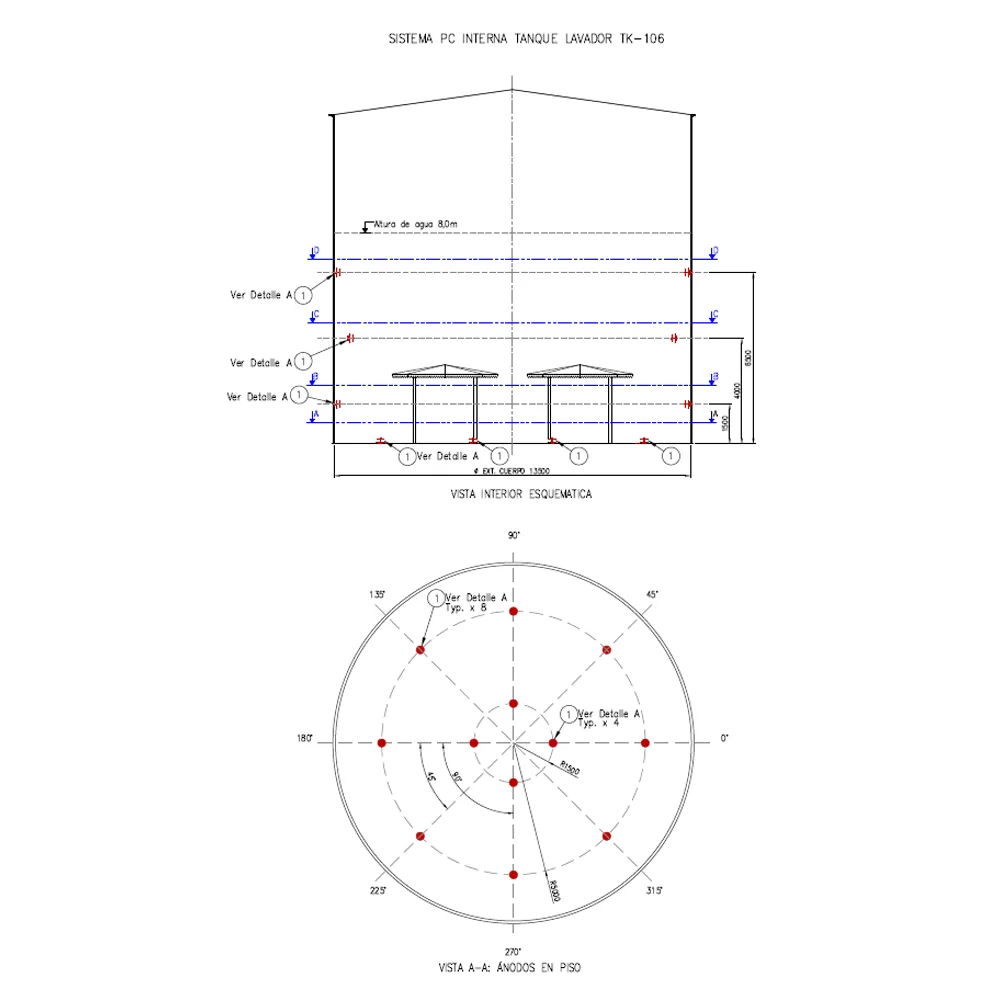

In this case, the design is focused on protecting the tank bottom, ensuring comprehensive coverage for buried tanks, where the entire surface in contact with the ground requires protection.

For galvanic systems, anodes are strategically positioned around or beneath the tank to provide consistent and effective corrosion prevention.

For impressed current systems, the design may incorporate a deep anode bed, where the optimal depth, quantity, and type of anodes are carefully determined. Alternatively, MMO wire anodes can be arranged concentrically beneath the tank bottom to enhance protection and ensure uniform current distribution.

Equipment & Materials Supply

We provide high-quality materials for cathodic protection systems, including:

- Galvanic anodes (magnesium, aluminum, etc).

- Impressed current anodes (MMO, graphite, etc).

- Rectifiers and accessories (reference electrodes, cables, weld connectors, etc).

Cutting-Edge Simulation Technology

Cathodic protection system designs for both the interior and exterior of tanks are simulated using boundary element models with Beasy CP® software.

Review and Validation of Existing Designs

If you already have a cathodic protection system design for your tanks, our AMPP CP4 specialist can review and validate the design to ensure its effectiveness and compliance.